| Your browser is not supported. | ||

|

Please browse our site using any of the following options:

| ||

Understanding Baffle Construction On A Sleeping Bag

Ever since company founder Rick White stitched together the first Mountain Designs sleeping bag back in the mid-1970s, we have been using world-class technology and manufacturing techniques. This allows us to achieve excellent quality, high performance sleeping bags that are fit-for-purpose and will meet the needs of your adventure. One of these manufacturing techniques is baffle construction. Here we explain what baffles are, the difference between each construction method, and how it affects the performance of the sleeping bag itself.

What Is A Baffle & Why Is It Important?

When constructing a sleeping bag or outdoor quilt, a series of chambers is stitched into the design to prevent the insulation fill from moving around inside. These chambers, known as baffles, hold the fill in place and allow it to fully loft, enhancing its ability to trap heat and keep you warm. In simple terms, these baffles are the horizontal (or sometimes vertical) lines you see in the design of your sleeping bag or jacket.

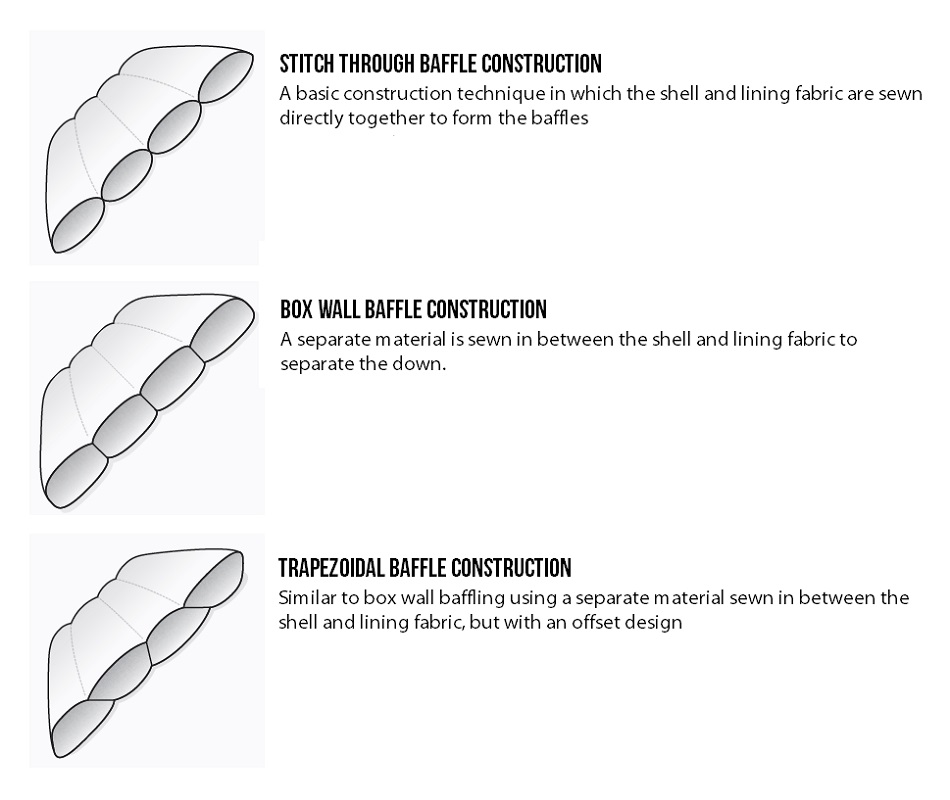

Each type of baffle construction technique brings with it certain pros and cons. When designing our sleeping bags, we select a method in conjunction with the different profile shape of the bag, the overall fill weight and its end use. The predominant baffle construction techniques we use are stitch through, box wall, and trapezoidal.

Baffles are the series of chambers stitched into the design to prevent insulation fill from moving.

Most baffling is horizontal, although variations will typically be found on jackets for aesthetics.

Types of Baffle Construction

Stitch Through Baffle Construction

Stitch through baffle construction (also known as sewn through) is a basic construction technique where the shell and lining fabric are sewn directly together to form the baffles. This creates a simple seam to separate the fill, making the baffles lightweight and easy to manufacture. It is often used for warmer weather bags as the stitching can cause cold spots at the seams where there is no fill and heat can easily escape.

Box Wall Baffle Construction

Box wall baffle construction is where a separate material is sewn in between the shell and the lining to create a 'box' to separate the down. This minimises cold spots found at the seams, and allows the down to loft up more efficiently. This is more complicated than stitch through baffling and therefore is more expensive.

Trapezoidal Baffle Construction

Developed by our very own Rick White, the trapezoidal construction uses a separate material to separate the fill, similar to the box wall baffle construction. However, the trapezoidal construction uses an offset design to eliminate cold spots between seams. The trapezoidal shape also improves the down dispersion within the baffles.

Curved Baffles

Curved baffles are employed to improve down migration, spreading the insulation evenly throughout the baffle and holding it in place when using the sleeping bag.

Common baffle construction techniques include: stitch-through (top), box wall (middle), and trapezoidal (bottom).

Curved baffles improve down migration ensuring an even spread of insulation within the bag itself.